Panasonic Showcases GaN, Thermal and Passive Solutions

As GaN moves from an innovative technology to mainstream production, Panasonic will be exhibiting real and exciting applications that harness the power of their gallium nitride power transistors. The newly released X-GaN™ gate driver optimized for high frequency switching unlocks the full performance of the X-GaN transistor while keeping design efforts to a minimum. A fine control is possible (0.5% about 99.5% at 50kHz). It benefits from built-in precise current source optimized for GiT transistors and built-in negative voltage source. The company will also show some GaN application examples: GaN-based compact power supply units and a GaN-based inverter for motors. Also a GaN evaluation environment, GaN power devices, power modules (GaN and SiC based), as well as a bidirectional ac-dc converter for power storage systems (SiC application example) will feature on the stand.

In addition, Panasonic will present its prototype of assist robots that applies X-GaN technologies at PCIM for the first time in Europe, to showcase one of its applications. Power assist suits for industrial use have been developed by Activelink Co., Ltd., one of Panasonic's in-house venture companies. Panasonic has applied inverter technologies of X-GaN to ActiveLink's assist suit equipped with motors that assist human body mechanics.

Panasonic will showcast with LDPGS the next step for the Pyrolytic Highly Oriented Graphite Sheet (PGS) portfolio which is the thinnest thermal solution in the world with an industry leading thermal conductivity of up to 1950 W/m K which is 5 times higher than common materials like copper. LDPGS (Low Density Pyrolytic Graphite Sheet) has been developed for Thermal Interface Material (TIM) and convinces thanks to lowest thermal resistance, easy handling and due to the fact that it enables highest system reliability. Through its flexibility and ability to be cut in any shape, it allows new solutions for thermal management challenges where space and weight restrictions are critical and conventional solutions like grease are not feasible. LDPGS graphite sheet consists of a 2D carbon matrix with a thickness of only 200 µm, which effectively disperses and transfers heat along Z direction, protecting sensitive electronics like server units, IGBT modules or common inventors from damage.

In order to cover the market demand and application's requirements, Panasonic have developed a new Power choke coil technology (high power SMD in 12x12 case size ETQP8MxxxJFA.). Based on metal powder, the Panasonic High Power SMD is suitable for high ripple current application (e.g. Engine System, Start& Stop system, Steering system, etc...). Panasonic High Power SMD is not only suitable as replacement for rod core coil, but also suitable for downsizing. Instead of using 13x13, 15x15 or 17x17 case size, Panasonic can offer its High power SMD in 12x12 case size with same or even better electrical characteristics. Therefore this will lead also to reduce the size of the component and reduce the space on the PCB. With its low DCR characteristics, low power dissipation can be achieved with Panasonic High Power SMD

Further passive components from Panasonic on display at PCIM Europe 2016 will include a wide variety of the company’s latest capacitors and resistors. Featured resistors will include current sensing resistors which are designed for low resistance to minimize power consumption. Panasonic offers a wide range of components in many different case sizes (0402 to 2512) and many resistance values. The metal plate technology (ERJM-series) and special constructions makes the parts suitable for harsh environments while maintaining their high reliability. The double-sided resistor element technology (ERJxBW-series) and wide terminal technology (ERJA, ERJB-series) is ideal for high power applications. The company’s current sensing resistors correspond to AEC-Q200 and therefore are well suited for all different kinds of automotive applications. Further technical details include a large power dissipation capability, soft termination to reduce the risk of solder joint cracking, high ESD resistance, and high pulse resistance.

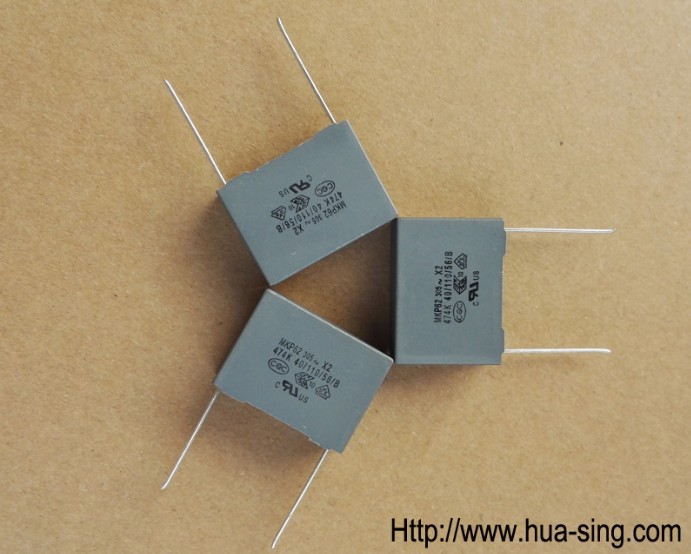

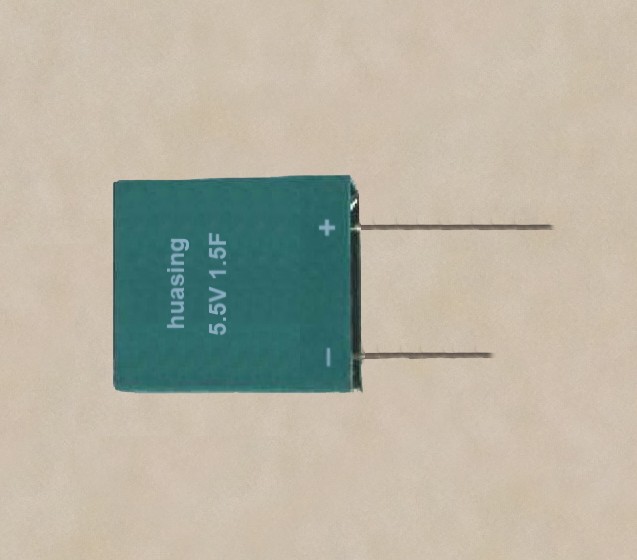

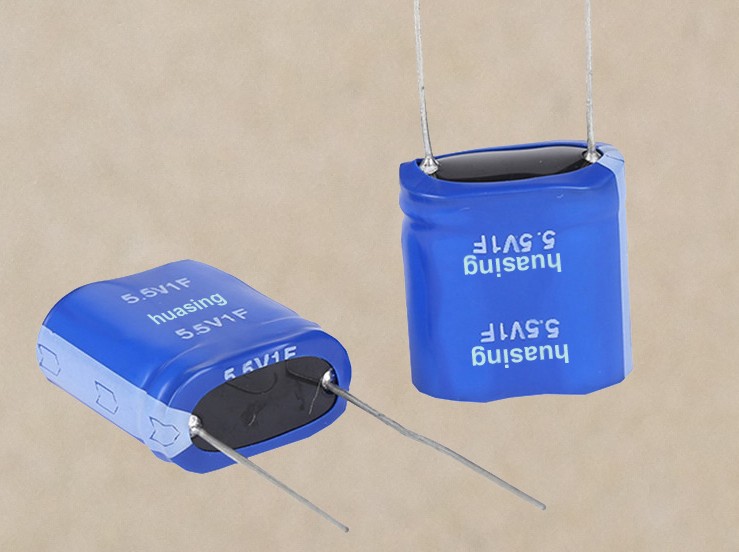

Featured capacitors will include Panasonic’s industry leading range of film capacitors and hybrid capacitors. The high reliability and high performance of the film capacitors facilitates the design of custom made modules that enable safe and robust designs for DC-link operation. The two lines of hybrid capacitors mark a perfect mixture of solid polymer and liquid electrolyte which allows high ripple current in very small sized capacitors. Stable characteristics over the whole frequency range and low ESR even at low temperatures support high power applications.

Tel:86 0513 65085106 Fax:86 0513 81164838

Tel:86 0513 65085106 Fax:86 0513 81164838